Realtime Systems

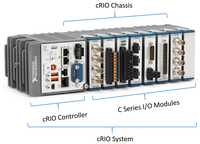

Alware has extensive experience in designing complete realtime systems, whether or not part of a production process or measurement setup. In a production environment, PLCs are often responsible for the control, for example of a conveyor belt system. If there is a need for realtime data analysis, these PLC systems are often not fast enough and the implementation of a realtime system can offer the solution. The used realtime systems have large computing capacity due to the presence of local programmable FPGAs, with which very fast data analysis can be achieved.

By using realtime systems production processes can be controlled locally with high speed. The controllers communicates with a remote PC (operator) wirelessly or not. This communication is also fast because data can be send in huge blocks because real time now is not necessary anymore. The most used realtime systems are very robust and can be easily implemented in a wide range of production processes. In this way, a very flexible robust solution is created with great computing capacity, that can serve both in stand alone systems and in existing (sub) systems or processes.

An example of a remote controlled real-time system in a production process, in which the pressure and force of 4 individually products are measured at the same time and analyzed every 0.5 to 1 second (adjustable). The appropriate calculations are done very fast using the code implemented in the FPGA on the local Real time controller. A number of errors have been formulated by the customer and these are shown as unique indicators on the screen. Every error indicator represents the number of ‘faults’ of the corresponding test or analysis.